Exact Analysis: Discover the Power of Our Materials Test Lab

Wiki Article

Professional Products Screening Laboratory: Ensuring Product Performance

By subjecting products to strenuous screening procedures, these labs give important understandings that help producers make educated choices. Partnering with an experienced products testing laboratory provides various benefits, including enhanced product quality, lowered danger of failing, and improved consumer complete satisfaction. In this post, we will certainly explore the relevance of products screening and why it is essential for guaranteeing product efficiency (materials test lab).

Significance of Products Testing in Product Advancement

Products screening plays an essential role in making certain the top quality and reliability of products throughout the development process. It involves subjecting products to various tests and analyses to examine their mechanical, physical, and chemical homes. Since it helps manufacturers determine if the materials made use of in their products satisfy the required standards and specs., this testing is crucial.One of the primary factors why products testing is necessary in item development is that it helps determine prospective weak points or imperfections in the products. By subjecting them to strenuous screening, manufacturers can evaluate their toughness, resistance, and toughness to use and tear. materials test lab. This information is crucial in making items that can withstand the demands of real-world applications and guarantee long-term performance

Materials screening likewise assists in optimizing item design and performance. By understanding the behavior of various materials under differing conditions, suppliers can make informed choices concerning choosing the most ideal products for certain applications. They can also recognize areas for enhancement and make required alterations to enhance item efficiency and integrity.

Additionally, products testing plays an important function in making certain item safety and conformity with regulative standards. By evaluating products for toxicity, flammability, and other security parameters, suppliers can recognize any prospective dangers connected with their products. This permits them to take required steps to alleviate these threats and guarantee the security of end-users.

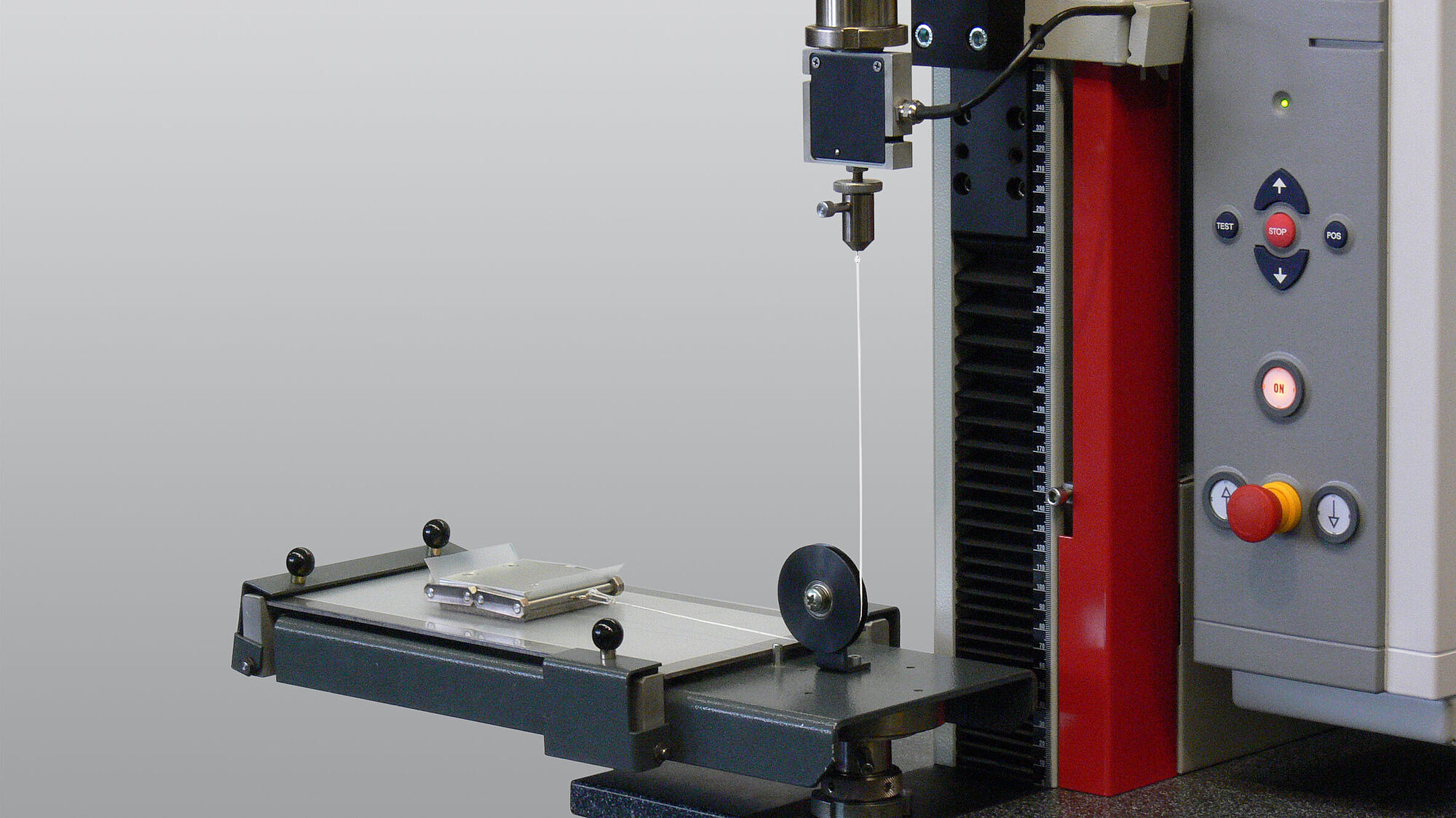

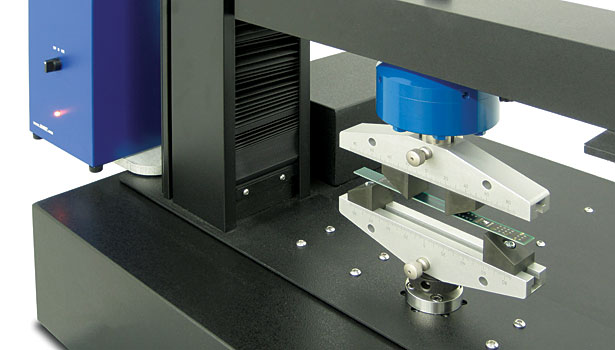

Kinds Of Examinations Carried Out in a Materials Screening Lab

A products screening lab performs a wide variety of tests to assess the properties and performance of different materials made use of in item growth. These tests are vital in making sure that products meet the called for requirements and carry out as anticipated in real-world problems. One generally performed examination is the tensile test, which determines the stamina and ductility of a material by subjecting it to stress up until it breaks. Compression examinations, on the other hand, examine a material's ability to stand up to compressive pressures. Tiredness examinations analyze a product's sturdiness by subjecting it to repeated loading and dumping cycles, mimicing real-life use problems. Influence examinations determine a material's resistance to unexpected and extreme pressures, such as those experienced throughout a collision. Various other tests include hardness testing, which establishes a product's resistance to indentation or scratching, and thermal screening to evaluate just how materials reply to temperature level changes. In addition, deterioration testing evaluates a product's resistance to deterioration and degradation in various atmospheres. By conducting these tests, materials examining laboratories make certain that manufacturers can depend on the efficiency and resilience of their items.Duty of Products Testing in Ensuring Product Top Quality

One key facet in guaranteeing item high quality is the duty of materials screening. Products screening plays a vital duty in figuring out the efficiency, integrity, and safety and security of an item. By subjecting materials to various tests and analyses, manufacturers can identify any kind of possible flaws or weaknesses that could jeopardize the top quality of the end product.Products screening assists in assessing the physical, mechanical, and chemical homes of materials used in the production procedure. This consists of screening for homes such as tensile toughness, corrosion, flexibility, and firmness resistance. Via these tests, producers can make certain that the products fulfill the needed specs and requirements.

By performing strenuous products screening, producers can obtain useful insights right into the actions and qualities of the products they utilize. This information allows them to make educated decisions regarding material choice, style improvements, and quality assurance measures.

Ultimately, the duty of products screening in ensuring product top quality is essential for generating trustworthy, durable, and high-performing products that fulfill consumer expectations and regulative needs. It helps manufacturers to recognize and resolve any possible concerns early in the production procedure, resulting in boosted item efficiency and consumer satisfaction.

Advantages of Partnering With a Specialist Materials Testing Laboratory

Partnering with an expert products screening laboratory uses numerous crucial benefits in making sure the performance and high quality of items. By collaborating with a specialized testing lab, organizations can tap into their comprehensive expertise and know-how in materials evaluation and evaluation. Among the main benefits is access to cutting edge testing tools and techniques that might not be offered in-house. These innovative strategies allow the laboratory to properly analyze the physical, chemical, and mechanical homes of products, giving important understandings right into their performance and longevity.An additional advantage is the objective nature of the testing process (materials test lab). Professional materials evaluating labs run separately and have no beneficial interest in the result of the examinations. This impartiality guarantees that the outcomes obtained are reputable and objective, allowing organizations to make educated decisions based upon the data supplied

Furthermore, partnering with an expert lab helps to enhance the testing procedure and decrease time-to-market. These laboratories have the essential sources and abilities to take care of a vast array of screening requirements successfully and effectively. By outsourcing materials screening, companies can concentrate on their core proficiencies and conserve important time and sources.

Additionally, teaming up with a professional products evaluating laboratory can boost a company's track record and trustworthiness. By having their items checked and licensed by a trustworthy third-party lab, companies can show their dedication to quality and client contentment. This can help build count on with clients and separate their items in the market.

How Products Screening Adds To Customer Fulfillment

Products testing plays an important function in guaranteeing consumer satisfaction with products. blog here By subjecting products to extensive testing, producers click over here now can evaluate their performance and quality, ensuring that they surpass or meet consumer expectations. This procedure helps to identify any type of prospective flaws or weaknesses in the materials, permitting makers to make needed improvements before the item reaches the marketplace.Customer fulfillment is directly affected by the performance and resilience of the items they buy. Materials screening helps suppliers examine the strength, adaptability, and toughness of products, making sure that products can stand up to the intended usage and carry out as expected gradually. By ensuring that items are made from top notch materials, suppliers can improve customer fulfillment by delivering products that fulfill their requirements and provide durable efficiency.

Along with performance, products testing also adds to customer safety and security. Evaluating materials for prospective dangers, such as poisoning or flammability, assists makers ensure that their items meet security criteria and regulations. By offering secure and reputable products, makers can construct trust with consumers, improving their total complete satisfaction and commitment.

Final Thought

In conclusion, materials testing plays an important function in product development by guaranteeing item efficiency and high quality. By conducting different tests in a products testing lab, makers can identify any defects or weaknesses in their products and make needed enhancements.One of the main reasons why materials navigate to this website screening is vital in item advancement is that it helps identify possible weak points or defects in the materials. By recognizing the actions of different materials under differing conditions, manufacturers can make enlightened choices regarding picking the most ideal materials for particular applications.A materials screening lab performs a vast range of tests to review the residential or commercial properties and performance of numerous materials made use of in product development. Various other tests consist of hardness screening, which identifies a product's resistance to imprint or damaging, and thermal testing to assess how materials respond to temperature modifications.In conclusion, products testing plays an important function in item growth by ensuring product performance and high quality.

Report this wiki page